1- Conventional & Advanced NDT

- Visual Inspection Testing.

- Radiographic Testing.

- Ultrasonic Testing.

- Magnetic Particle Testing.

- Dye Penetrate Testing.

- Long Range Ultrasonic testing (LRUT) for buried and aboveground Pipelines/piping.

- Pulsed Eddy Current Testing (PEC) for general corrosion detection for insulated piping, Tanks and vessels

- Tube Inspection – Acoustic Eye, IRIS,RFET

- Magnetic Flux Leakage Inspection (MFL) for Tanks

- Phased array and Inspection for Plant Piping, Tanks & Pressure Vessels etc. (Onshore &Offshore)

- High Speed Corrosion Mapping by Automatic Rapid Motion Scanner (RMS) & Manual Corrosion Mapping.

- Project Management Institute (PMI).

- Time-of-Flight Diffraction (TOFD).

- Hardness test.

- Ferrite test.

2- Post welds heat treatment.

3- Welding (piping, tanks, pressure vessels, pipeline and steel structures)

4- Carrying out Repair & Maintenance by welding

5- Consultations

- Prepare a Welding Procedure Specification (WPS )According to The requirement OF CODE Standard

- Prepare a Procedure Qualification Records (PQR )According to The requirement OF CODE Standard

- Material selection studies

- Study of the failure causes & services

- Carrying OUT MECHANICAL & CHEMICAL TESTS

- Issue of Technical Reports

Equipment List:

|

Serial No. |

Description |

Manufacturer |

Model |

Qty |

|

1 |

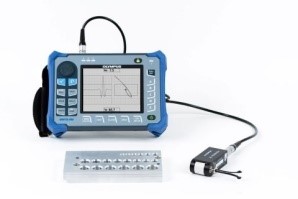

Phased Array |

OLYMPUS |

Omi-Scan |

3 |

|

2 |

PMI X-Ray Fluorescence Spectrometer |

Innovative X-Ray

Technologies USA |

2000 AS

|

2 |

|

3 |

Ultrasonic Flaw Detector | STARMANS | DIO 1000 SFE |

2 |

|

4 |

Ferrite Meter | DIVERSE | MF 300F+ |

1 |

|

5 |

Contour Probe YOKE |

Parker Research Corporation |

DA 400S |

1 |

|

6 |

X-Ray machine |

MITECH |

XXG-2505 |

1 |

|

7 |

Hardness Tester |

EQUOTIP | D Type |

1 |

|

8 |

Survey Meter |

NDS |

NDS-2000 |

2 |

|

9 |

Dosimeter | Arrow-Tech |

W138 |

2 |

|

10 |

Ultrasonic Thickness meter |

Diatonic |

EHC-09B |

1 |

|

11 |

Painting Thickness meter |

Coates |

1000 |

1 |

|

12 |

Thermometer |

Fluke |

566 Dual |

1 |

|

13 |

Clamp ampere |

Eyesigh |

U1211A Clamp

|

1 |